Sen̓áḵw Design Presentation and Site Tour

June 3, 2025

Scott Kennedy Duplex Presentation and Site Tour

June 19, 2025

June 2025

Written by: Homeowner and Natalie Douglas, ZEBx Program Manager

North Van Net Zero is a two-time Georgie and HAVAN award-winning project and the North Shore’s first certified whole home net zero energy retrofit, showcasing innovation in sustainable building. Our project emphasized deconstruction and material reuse, air tightness and insulation, and solar power integrated with a fully electrified system designed to improve comfort and resilience. We achieved our goals, faced and overcame complex design and permitting hurdles, and learned many lessons along the way, which we share below.

Curious how an aging home was transformed into a model of sustainability and performance? This case study is a must-read for homeowners, builders, architects, and policymakers seeking real-world insight into achieving net zero energy in existing homes. We’re pleased to pass along what we learned with the hope of making your journey easier.

Prefer to Catch Up with a Video and/or Podcast? You can check out the March 2025 ZEBx Decarb Lunch webinar here that featured this project.

| Building type: Single-Family Bungalow | Location: North Vancouver, BC |

| Year built: 1958 | Year retrofit complete: 2024 |

| Climate zone: 4 | Heating degree days: 2910 |

| Foundation type: Concrete (Full Basement) | Structure type: Wood-framed |

| Floor area of conditioned space: 261.30m2 | Deep or phased retrofit: Deep retrofit – complete building and systems overhaul |

| Annual energy savings: 77.8% | Operational carbon savings: 8.1 tCO2/yr |

What We Set Out to Do – Project Aspirations

The primary goals of this renovation project were to modernize the layout and aesthetics while increasing performance. We aimed for a fully electric, net zero energy home supported by on-site solar to meet the home’s total annual energy demand. We preserved the original footprint of the 1958 house and existing yard, adding only 150 square feet to better accommodate our active family. Our design team adopted the pragmatic “Pretty Good House” philosophy – focusing on high performance and resilience regardless of whether the title of Net Zero was achieved. We also prioritized embodied carbon modelling, low-carbon material selection, and extensive reuse of the existing structure.

What We Achieved – Project Highlights

- Met our net zero energy design and all-electric goals (including meeting BC Energy Step Code 4, which means our home is higher performing than a considerable number of new homes in the province).

- First CHBA-labelled Net Zero Renovation on the North Shore

- Deconstruction and material reuse prioritized; over 80% of construction waste diverted from landfill

- Triple-glazed windows, R-22 to R-60 envelope insulation, no sub-slab insulation due to retention of original foundation

- Air tightness improved from 9.37 ACH to 1.08 ACH (~1.5 times better than the mandatory minimum performance for new Part 9 homes)

- Energy consumption reduced by ~80%, from 185 GJ/yr to 41 GJ/yr; carbon emissions reduced from 8 tCO2e/yr (almost 2.5 times as much as the entry level of the Zero Carbon Step Code) to just 0.125 tCO₂e/year. The installed solar PV system generates sufficient electricity to meet the home’s energy demands, achieving net zero operational carbon emissions.

- Embodied carbon modelled at 120 kgCO2e/m2, around 40% less than the City of Vancouver average for homes

- Low-carbon concrete at 194 kgCO2/m3, a ~50-70% reduction vs Canadian ready-mix concrete baseline (~30% reduction vs BC baseline)

- Solar PV system of 27 panels, 570 ft2 array size, generating 43 GJ/year estimated on-site renewable energy

- EnerGuide rating of 0 GJ, indicating that the home produces as much or more energy than it consumes annually

What We Built – Building Envelope & Mechanical System Details

| Natural gas and wood-burning fireplaces, gas furnace, forced air & electric baseboard heat | Pre-renovation | Post-renovation |

|---|---|---|

| Heating and cooling | Natural gas and wood-burning fireplaces, gas furnace, force air & electric baseboard heat | 3-Ton Carrier 30MURA cold climate air source heat pump |

| Water heating | Gas water heater | Rheem ProTerra hybrid electric heat pump hot water tank |

| Insulation | R0 basement, R8 walls, R24 attic | R22 basement, R24 walls, R60 attic (combined batts and blown fibreglass insulation). GPS for foundation walls. HFO-based spray foam in select areas for cold floors. |

| Air barrier | Wood, solid and hollow core. Aluminum and wood single-glazed windows and sliding doors. | Solitex Mento 1000, Intello Plus, Tescon Vana taped joints, select spray foam. Concrete for foundation and slab. |

| Roof | Hip roof design, hand-framed, asphalt roofing | Gable roof design, roof trusses with select hand framing, asphalt roofing |

| Doors and Windows | Wood, solid and hollow core. Aluminum and wood single-glazed windows and sliding doors. | Fibreglass polystyrene core Westeck doors. Triple-glazed french doors (front/back deck). Vinyltek triple-glazed windows USI 0.97-0.91, SHGC 0.16-0.19 with low emissivity coatings. |

| Ventilation | N/A | Fantech HERO series HRV 81% SRE @ 0 degree C (balanced ventilation) |

| Air tightness | 9.37 ACH @ 50 Pa | 1.08 ACH @ 50 Pa |

| Renewable energy | None | 27 Qcell Q.PEAK Duo solar panels, 11.07kW system size. AP systems microinverters. |

| Drainage | 8.8 L/s stormwater flow rate, impervious driveway | <0.68L/s stormwater flow rate, subsurface Brentwood box, permeable driveway |

| Wildfire resilience | Extreme fire hazard assessment – wood cladding, vinyl soffits and fire-prone vegetation adjacent to the home | Improved fire hazard assessment – non-combustible siding, fire-retardant treated soffits, firesmart planting and landscaping |

What We Learnt – Setbacks, Wins, & Other Key Takeaways

Pursue Integrated Design

The project’s success was shaped by an early commitment to integrated design, with collaboration between the designer, builder, consultants, and energy advisor beginning at the outset. As homeowners, we were actively involved throughout the project, championing sustainable design goals, helping maintain alignment across disciplines, ensuring the project stayed focused on its performance objectives, and documenting the process to help educate and inspire others (see our blog here). Although the level of engagement across the team varied as the project progressed—something future project teams may want to anticipate—the integrated design process ultimately laid a strong foundation.

Tip: Don’t Neglect These Details Some technical details that are not often top of mind for contractors and trades but warrant sustained attention for resilient net zero design:

- confirming appropriate heat pump sizing for a well insulated envelope — industry “rules of thumb” do not apply

- prioritizing low carbon materials such as concrete and insulation – these may be readily available but are not always asked for or specified by default.

- future-proofing goals around EV energy storage and back-up power – even if you’re not buying a battery system now you can future proof for this possibility.

- energy monitoring and control systems — these are not required by codes but very useful to verify energy consumption, solar production, control car charging to avoid demand spikes etc.

These are not always standard practices, so it’s worth building in time and resources to verify such elements.

The construction phase was remarkably smooth, thanks in large part to consistent on-site project management that kept communication flowing and trades aligned. This kind of steady, detail-focused oversight proved invaluable, especially in a high-performance build with an atypical architectural form. The trust built with the team along the way also helped streamline the selection of systems and materials that supported the home’s net zero energy goals, such as low-carbon materials, heat pumps, triple-glazed windows, and high-efficiency insulation. The project achieved an airtightness level of 1.08 ACH, a notable accomplishment given the home’s complex geometry. This outcome reflects not only good planning but also a strong, shared commitment to performance throughout the build phase, including bringing in expert consultation where warranted to meet goals.

| Design | Mark Kerschbaumer |

| Contractor | Twin Lions Contracting |

| Energy Advisor | Capital Home Energy |

| LCA | Carbon Wise |

| Structural | Inform Engineering |

| Envelope | Richard Kadulski |

| Insulation | Four Seasons |

| Electrical | Reliable Electric |

| Mechanical & Plumbing | Airstream, SMR |

| Interior Design | Triple Dot Design Studio |

| Deconstruction | Unbuilders |

Consider Whole Life Carbon

Transforming an older home into a model of sustainability takes more than energy efficiency upgrades—it requires looking at the full climate impact of every decision, from materials to mechanical systems. While operational energy use often dominates the conversation, embodied carbon—the emissions tied to manufacturing, transporting, and assembling building materials— is also a consideration. Together, these two sources form a building’s whole life carbon footprint.

For this project, we set out to reduce both operational and embodied emissions wherever possible. Early on, we commissioned a whole-building life cycle assessment (wbLCA) to compare the embodied carbon of our deep retrofit with a hypothetical teardown and rebuild. While the retrofit approach allowed us to retain the existing foundation and structure, our project was ultimately reclassified as a substantial reconstruction, requiring underpinning and significant amounts of new rebar and concrete. As a result, the embodied carbon savings were narrower than we had hoped.

Because of the reclassification, the cost of rebuilding from scratch would likely have been comparable—or even lower—than the retrofit, and the process far less complex. But we chose to retrofit to demonstrate what’s possible—and along the way were able to highlight the need for better policies and incentives that make deep carbon reductions in existing homes not just possible, but preferable.

The largest contributors to our project’s embodied carbon were:

- Concrete slab, footings and foundation: Reuse of the concrete scope was originally projected to save around 32% of total home embodied carbon (~9 tons CO2). Unfortunately, additional concrete was subsequently required to allow foundation reuse while meeting increasingly stringent seismic requirements, including shear walls, 6” increased foundation height, updated piers + footings, which, despite using low-carbon concrete, put a dent in these savings.

Setback – Substantial Reconstruction Reclassification: A major challenge in the project stemmed from the fine – and seemingly steep – divide between deep renovations and full new builds. Deep energy retrofits necessarily involve substantial reconstruction of the full building envelope to achieve optimal R-values and air tightness. In the case of our project, this triggered a cascade of regulatory hurdles related to foundation reuse and evolving seismic, stormwater, and wildfire resilience requirements.

A pivotal moment came mid-project when, due to an increased deconstruction scope, BC Housing reclassified the home as a “substantial reconstruction” under the Homeowner Protection Act. This decision had major ramifications for the project increasing financial and embodied carbon costs and leading to an additional 5 month permit delay. The same designation later meant that we were ineligible for CleanBC rebates, intended to support home energy efficiency and decarbonization.

The fine line between renovation and rebuild and large increase in cost and permitting requirements of the latter is worth underlining. This makes pursuing a deep energy retrofit that goes down to studs and foundation down a risky proposition, and may serve as a disincentive to home decarbonization projects of this sort. There is currently no clear solution to this regulatory gap. We’ve engaged in advocacy with BC Housing and CleanBC to raise awareness of this issue, and ZEBx will continue to support and advance this conversation in hopes of enabling more climate-aligned retrofit pathways.

- Roof: The roof was replaced to accommodate improved insulation, daylighting, and solar PV. Through the wbLCA, we learned that the new roof would represent 38% of the home’s embodied carbon if metal roofing was selected (10.8 tons CO2) or 25% if asphalt shingles were selected (5.9 tons CO2). These figures are inclusive of the roofing material, framing and insulation. Roofing materials alone represented 20% (steel panels) or 3% (asphalt shingles) of the project’s embodied carbon, respectively. While metal roofing has a significantly higher carbon impact, its longer lifespan (40-70 years) and recyclability at both ends of the life cycle make it a compelling choice. Ultimately, we selected asphalt roofing for cost reasons in addition to the benefit of a similar renewal timeframe to solar (25-30 years).

- Windows: Our windows ended up representing 17% of the project’s embodied carbon (4.7 tons CO2). We selected triple-pane windows over double-pane options, despite their higher embodied carbon, due to their superior thermal performance (higher R-values). Because windows are typically the least insulated part of a building envelope, enhancing their performance was a key strategy for reducing overall heat loss. In addition to reducing heat transfer, triple-pane windows offer improved sound insulation and help maintain a more consistent indoor temperature near the glass.

- Cladding: Approximately 12% of the project’s embodied carbon—3-4 tons of CO₂—came from the non-combustible Hardie board fibre cement siding. This material was chosen to meet the project’s wildfire resilience requirements and to ensure long-term ease of maintenance.

- Insulation: Our insulation represented 6-10% of the project’s embodied carbon (1.5-2.8 tons CO2). Insulation is key for driving down operational emissions by providing thermal resistance and air tightness, but it can also play a role in reducing embodied carbon. We found that there were low carbon options that were readily available and could help drive embodied carbon down by up to 30% without compromising performance.

Win – Adapted Floor-Area Calculations: The District of North Vancouver made a small accommodation to exclude insulation from floor-space ratio calculations, which helped us meet our high performance targets without compromising on the intention to increase space for our busy family. This seemingly minor adjustment can have a major impact, empowering more homeowners to pursue energy-efficient designs.

- Structure: The original structure was carefully deconstructed, with over 80% of waste diverted from landfill. We managed to maintain the bulk of the original foundation as part of the renovation, in addition to over 200 studs and 2x10s (approx ~ 4540 board feet of lumber) utilized in the rebuild. Materials that were unable to be retained or repurposed on-site were donated to Habitat for Humanity and Heritage Lumber. Our home was featured as a case study for BCIT’s first Deconstruction Management Course, launched in September 2022.

By conducting a whole-building life cycle assessment (wbLCA) early in the project, we were able to evaluate both embodied and operational carbon and prioritize interventions that would deliver the greatest overall emissions reductions. While embodied carbon rightly deserves attention, particularly in new construction, our analysis revealed that the operational emissions from our older, gas-dependent home far outweighed the embodied impacts of the retrofit (operational carbon savings = 10x embodied carbon impact over a 50-year lifespan). This allowed us to focus our efforts where they would have the biggest climate return: improving insulation, airtightness, and mechanical systems. Our original home emitted roughly 8 tonnes of CO₂ per year, totalling more than 400 tonnes over 50 years—making operational improvements not just necessary, but urgent.

Many post-war rancher renovations focus on surface-level upgrades—what some call “lipstick renovations”—without addressing the building envelope or fossil-fuel reliance. But without tackling these root issues, homes like ours continue to lock in decades of avoidable emissions. For deep emissions reductions, both the structure and the systems need to be reconsidered—and a wbLCA can provide the clarity needed to make the right calls.

Since switching to an all-electric system, our home now operates near zero emissions, with a carbon payback period of just five years. This means the avoided operational emissions offset the retrofit’s embodied carbon in that time, and we’ll then save on average 8 tonnes of CO₂ every year. Retrofitting older homes with improved insulation, airtightness, and electric systems is not just essential for the climate; it also delivers markedly better comfort.

Ultimately, our experience revealed that deep retrofits are complex and often financially challenging. Current policies, permitting processes, and financing options frequently fall short and can unintentionally favour demolition over preservation or deconstruction. To truly decarbonize our housing stock, we need more flexible regulations, accessible and updated incentives, and financial tools that acknowledge both the urgency of climate action and the practical realities homeowners face. Deep retrofits are difficult but achievable. With the right support, they can become more widespread, affordable, and central to a low-carbon future.

Tip – Refer to CLF BC’s Sourcing Guide: Check out CLF BC’s Low-Carbon Material Sourcing Guide to find specific low-carbon building products in BC. You can find products in the following five groupings: insulation, rebar, cladding, ready mix concrete, and novel materials.

Design for Resilience

With climate and natural disasters becoming more frequent, there was an opportunity in our project to include design elements that would future-proof our home and add resilience. By integrating features like stormwater management, wildfire resistance, and wiring for EV battery backup, we’ve taken steps to make our home more adaptable, safe, and equipped for what’s to come.

Stormwater Management

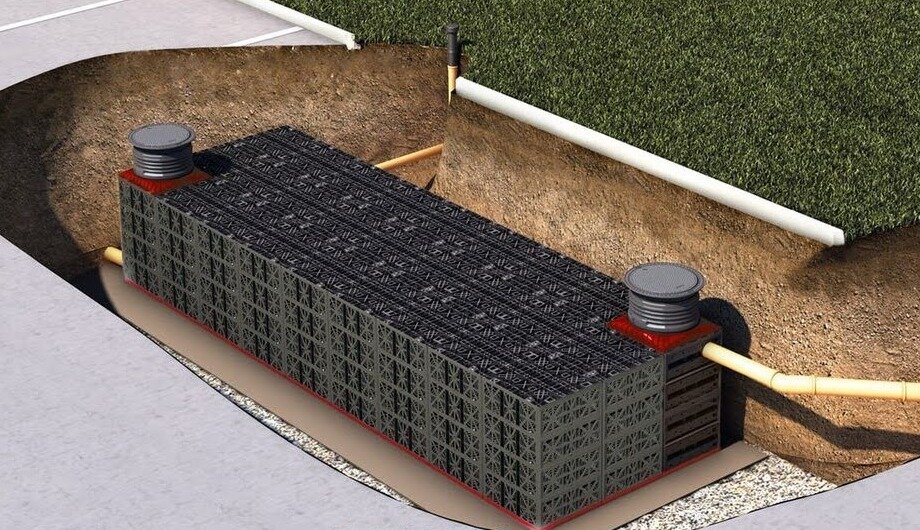

Managing rainwater on our property was a known challenge due to the area’s dense, clay-rich soil. When the District of North Vancouver (DNV) required a stormwater management plan (SWMP), we collaborated with our team to design a high-performing system that included underground retention tanks, multiple sumps, and a permeable driveway to absorb runoff and improve on-site drainage. This approach reduced peak site runoff from 8.8 L/s to less than 0.68 L/s, helping to divert water away from the home during extreme rain events and easing pressure on the municipal stormwater system.

Wildfire Resilience Local Wildfire Regulations

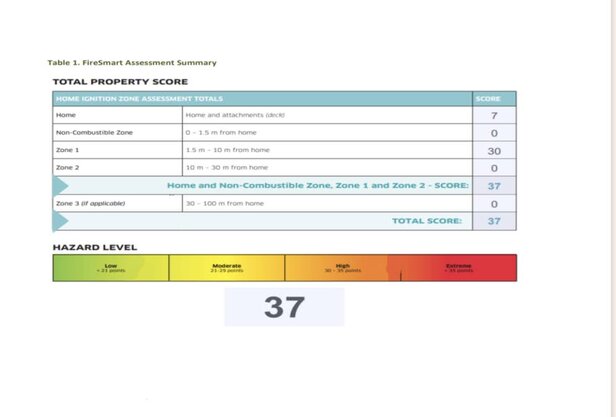

Living at the edge of a wildfire interface zone meant that our project was required to meet Wildfire DPA regulations and complete both Fire Hazard and Arboriculture Assessments. The timing of these requirements halfway through the build phase required us to revisit several key design decisions—from fire-resistant venting and penetrations to window framing, non-combustible cladding, and soffits treated with fire-retardant coating. Even the decking, hardscaping, and fire-resilient landscaping had to meet specific criteria, with final planting signed off before occupancy could be approved. By integrating wildfire resilience from the earliest design stages, we reduced our FireSmart risk score from 60 (Extreme) to 37 (High) and secured long-term protection through a covenant on the property title that will help safeguard the home for years to come.

Energy Storage and Backup Power

When we installed solar panels, we quickly discovered that adding a home battery wasn’t as simple—or cost-effective—as we’d hoped. Standalone batteries are expensive and relatively limited; for example, a Tesla Powerwall costs around $12,000 for just 13.5 kWh of storage. In contrast, our Kia Niro EV holds 60 kWh—four to five times more, just sitting in the carport. Unfortunately, full vehicle-to-home (V2H) backup isn’t widely available yet. Most EVs are built to charge from the grid but not to return power back to the home. While vehicle-to-load (V2L) features are becoming more common, they’re not designed to support whole-home backup. In consultation with our team, we installed a separate essentials panel, transfer switch, and a future-ready connection point for an EV battery. This way, when the technology catches up, we’ll be ready to power critical systems during outages—directly from the car.

Final Thoughts

Eight months into living in our net zero energy home, the results have been promising and rewarding. Early energy monitoring suggests the home is performing well against its modelled expectations. In October 2024, it generated 70% of its energy on-site. Even during the winter months, when solar production was lowest and energy demand highest, the home still produced over 30% of its own power. By April, with longer days and warmer temperatures, the house began generating significantly more energy than it consumed.

Our stormwater system has also proven resilient, effectively managing at least two atmospheric river events, including one that brought 250 mm of rain over three days. Structurally, the home has withstood seismic activity in the region, up to a magnitude 5.1 earthquake, without any visible damage to the concrete slab or building envelope.

From a comfort and livability standpoint, the thick walls, triple-glazed windows, and high-performance insulation have made the home remarkably quiet and thermally stable. Daylighting has transformed how we experience the space, allowing natural light to move through the house throughout the day. Our air-source heat pump has performed reliably, keeping us warm even in below-zero temperatures. The solar panels—one of the home’s most visible features—have sparked many curious conversations with neighbours, helping to normalize and inspire interest in clean energy solutions. We’ve also installed a circuit-level energy monitoring system to track performance across key systems, including the EV charger, range, heat pump, and solar array. We look forward to sharing our performance data with ZEIC’s Near Zero 4 Program, to help deepen our collective understanding of how high-performance homes operate in the real world.

If you’re considering your own retrofit journey, here are a few things we learned:

- Prioritize envelope upgrades—windows, insulation, and airtightness make a big difference.

- Go electric and consider solar if your site allows.

- Ask for low-carbon materials when procuring—your choices help shift the market.

- Engage an energy advisor or integrated design team early—they can help model scenarios and chart a course.

- Commit fully to your vision—you are your own best advocate.

- Make sure you get along with your builder, especially the project manager—1000+ decisions and inevitable trade-offs will be much easier if you trust one another.

- Stick to simple forms—deep retrofits are more straightforward with minimal structural reconfiguration.

- Understand your local policies and permitting context—some municipalities are more enabling than others, and the permitting experience can make or break a multi-year project.

We share this case study to help answer a growing and urgent question: how can aging homes be transformed into models of sustainability and performance? In our project, we set out to reduce whole life carbon, preserve as much of the existing structure as possible, and show what’s achievable when ambitious climate goals are paired with practical strategies. Along the way, we encountered regulatory hurdles, design trade-offs, and moments of uncertainty—but we also gained a wealth of insight we hope can help others. The path to low-carbon retrofits isn’t always straightforward, but it is navigable—and with better policy support and shared learning, these projects can become the norm rather than the exception.

Further information about this project:

- Blog (information compiled similarly on Instagram)

- Project Timeline

Technical documents:

- Baseline & As-Built Energuide Homeowner Information Sheets

- BC Step Code 4 Compliance Checklist

- Carbonwise Life Cycle Assessment

In the News: